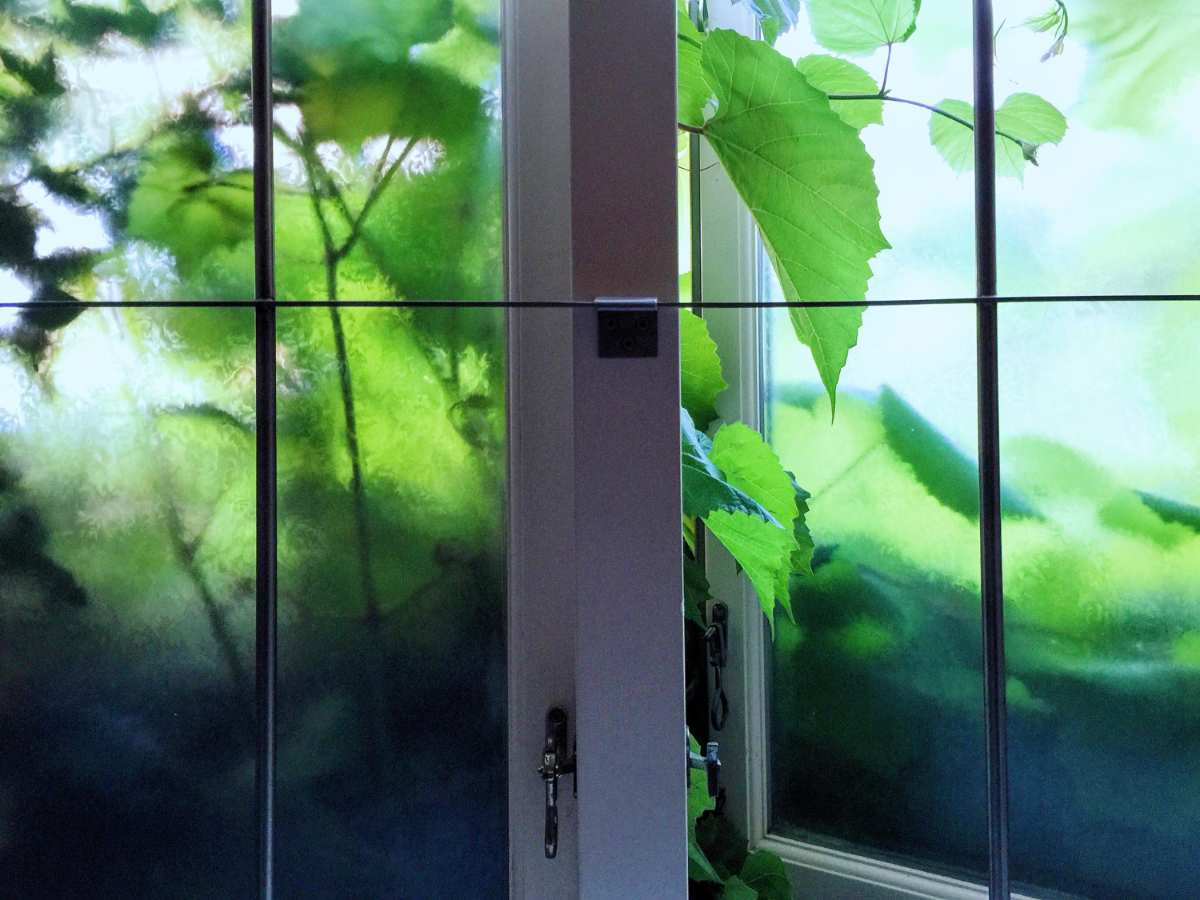

Ecological profile solutions in modern window systems

Ecological PVC profiles for windows: using recycled materials, safe materials, and principles of circular economy for sustainable construction.

Eco-friendliness in window systems today means not compromising on quality, but using technologies that reduce the burden on the environment without losing operational characteristics. For manufacturers of profile systems, this is a matter of materials, energy consumption, and the full life cycle of the product – from raw material extraction to recycling.

The market is changing, and customers are increasingly paying attention not only to thermal insulation or design but also to what the window is made of and what impact it leaves behind.

Recycling, or how old windows become new

The use of recycled plastic is becoming the norm for the window industry. PVC is a material that can be recycled many times without losing its key properties. Instead of old constructions ending up in landfills, they are crushed, thoroughly cleaned, and transformed into quality raw materials for new systems.

In simple words about complex technologies:

- The "sandwich" principle (co-extrusion): A modern window consists of strong recycled plastic on the inside, while the outside is covered with a layer of perfectly white "new" PVC. This allows the profile to be eco-friendly while maintaining its aesthetic appearance and resistance to sunlight.

- Energy savings: Producing profiles from recycled materials consumes 90% less energy than creating plastic from scratch. This significantly reduces carbon emissions into the atmosphere.

- Durability without compromise: The use of recycled materials does not make the window weaker. It holds its shape just as well, retains heat, and lasts for decades while helping to conserve the planet's resources.

What is "green" PVC in practice

"Green" PVC is not a separate material, but a comprehensive approach to production. It includes the following aspects:

- Refusal of toxic stabilizers: Replacing lead with safe compounds of calcium and zinc.

- Use of safe additives: Control over the chemical composition of all components.

- Environmental control: Monitoring emissions at every stage of production.

- Circularity: The possibility of multiple recycling (up to 7–10 times) after the end of its service life.

For the end user, this means safe windows without harmful emissions, stable characteristics, and full compliance with modern EU environmental standards.

Low carbon footprint and energy efficiency

One of the key indicators of ecological sustainability today is the carbon footprint. It is formed taking into account the energy expended on production, transportation, and operation of the product.

Energy-efficient profile systems reduce this indicator twice:

- At the production stage: Due to optimized processes and the use of renewable energy.

- During operation: Through a radical reduction of heat losses in the building over 30–50 years of service.

That is why modern ecological solutions are inextricably linked with multi-chamber profiles, high-quality seals, and airtight constructions.

Ecological sustainability without compromise

It is important to understand that a "green" profile does not mean less strength or durability. On the contrary, such systems are designed to withstand high loads and extreme temperature fluctuations.

Benefits for the consumer:

- Service life of 30 years or more.

- No need for complex specific maintenance.

- High level of heat retention and sound insulation.

- Compliance with the highest safety standards.

What solutions really work today

The most effective systems are those that combine several approaches simultaneously:

- Recycling: Use of recycled PVC in the core of the profile.

- Geometry: Multi-chamber structure for maximum energy efficiency.

- Safety: Eco-friendly stabilizers (Ca-Zn).

- Energy management: Production with strict control of energy consumption.

Does recycled PVC affect the strength of the profile?

No. The recycled material undergoes thorough cleaning and granulation. It is used in the inner layers and does not compromise on physical properties compared to primary PVC.

Are eco-friendly PVC windows safe for residential premises?

Yes. They do not emit harmful substances, have no odor, and are recommended for use even in children's and medical institutions.

Are eco-friendly profiles more expensive?

Not always. Thanks to production optimization and the use of secondary raw materials, the price difference is often minimal or even non-existent, but the value of such a product is significantly higher.

What is more important - environmental friendliness or energy efficiency?

These parameters complement each other. A good energy-efficient window is an eco-friendly solution, as it reduces fuel consumption for heating the house.

Can a window be recycled after its service life?

Yes. Modern profile systems are designed with the concept of sustainable development in mind, allowing for their complete recycling.

We will contact you shortly, provide all the necessary information about the products, and make a cost calculation.

- Spain (España)+34

- France (La France)+33

- Italy (Italia)+39

- United Kingdom+44

- Ukraine (Україна)+34

- Belgium (België)+32

- Switzerland (Schweiz/Suisse)+41

- Germany (Deutschland)+49

- Netherlands (Nederland)+31

Our Contacts

Spain

Call us now

Write to us